Valve trays

Single pass valve tray DN 1600 in stainless steel

The valve tray is the most common tray installed in the references in the whole world. These trays have a good efficiency whatever the flows are. The low-pressure drop is also one of their good advantages. The valves manufactured by KEMPRO may be fixed valves or mobile valves depending on the operation.

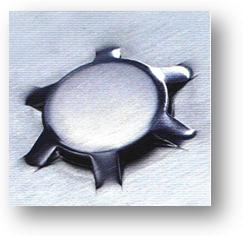

Valve AV

Operation principle The liquid is flowing from one tray to the next one by gravity through a down comer. The vapour is coming up trough the circular holes partially plugged by a valve. This forces the vapour to “bubble” in the liquid. Some elements originally in the liquid are “vaporated” in the vapour and some elements originally in the vapour are “dissolved” in the liquid. This mass transfer may take place in a distillation as well as in absorption.

Erection and layout The valve trays as every tray are designed in elements, which may be introduced through the manhole of the column and are generally fitted on a circular ring by clamps For a good operation the flatness of the trays is very important. Up to three meters of diameter, the beam incorporated to the tray will lead to a satisfactory flatness ; above it a support beam is generally recommended. The spacing between the trays is an important concern a major part of the mass transfer is made between the trays. We generally recommend 600 mm , but for lower diameter (less than 1 meter ) we might design the spacing down to 400 mm . The valve trays are generally designed with lateral weirs, bit for high diameter (above 2 meters ) central weirs may be required in order to better distribute the liquid phase.

Valve CO

|