Structured packing The structured packing is a relatively new packing. This packing is really appreciated for its good efficiency and its low-pressure drop. These two major properties often drive to a real gain in sizing the columns compared to the other mass transfer internals. KEMPRO structured packing is manufactured from corrugated sheets, arranged in parallel to each other. The corrugated sheets are assembled into an element at a fixed angle to the vertical axis : 45 ° or 30 °. The different types of structured packing manufactured by KEMPRO are named as follows : • the type of material (M for metal, P for plastic) • the specific surface area of the packing (from 125 m2/m3 to 750 m 2 /m 3 ) • the angle of the inclination of the channels with the vertical axis of the column (30 or 45°).

KEMPRO is manufacturing twelve types of packing : - metal structured packing :

- plastic structured packing :

KEMPRO structured packing may be supplied in many different types of materials : - stainless steel, aluminium, hastelloy, inconel, titanium... - PP, PE, PCV, PVDF,…

Operating mode The assembling of corrugated sheets in an element allows at the same time a uniform distribution of the ascending gas phase and of the descending liquid phase and an optimum contact for both phases. The main feature of the KEMPRO structured packing is its low-pressure drop at a given specific surface area.

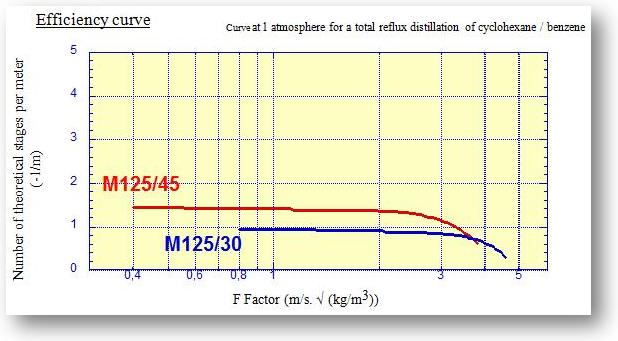

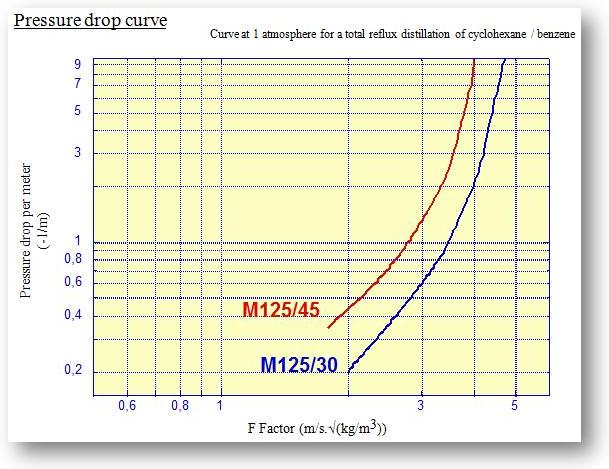

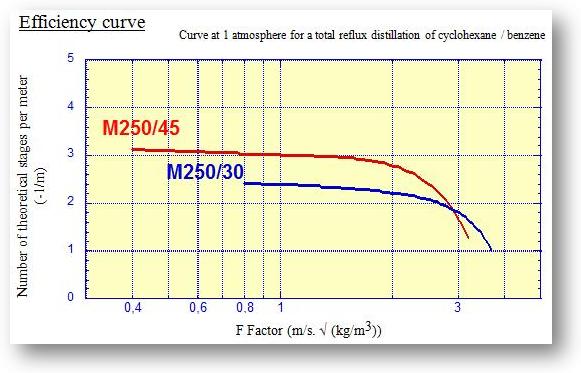

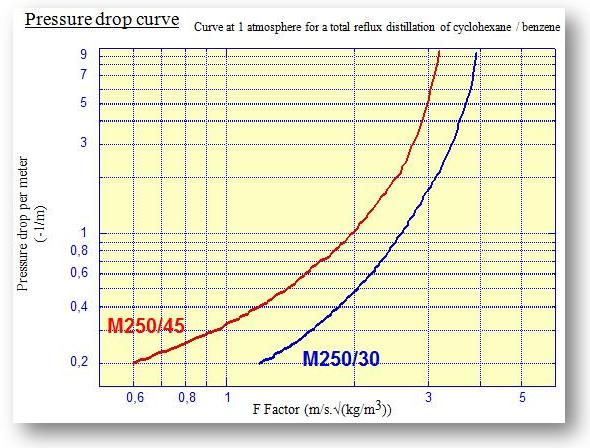

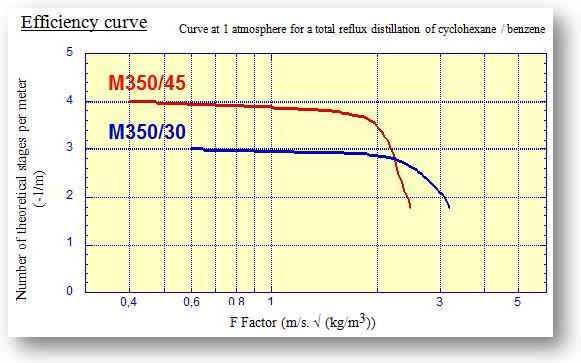

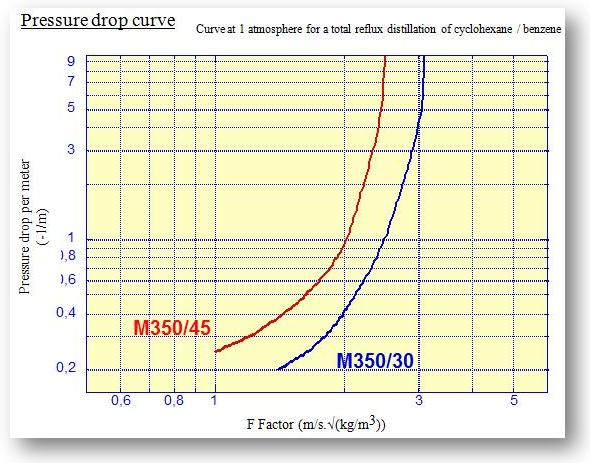

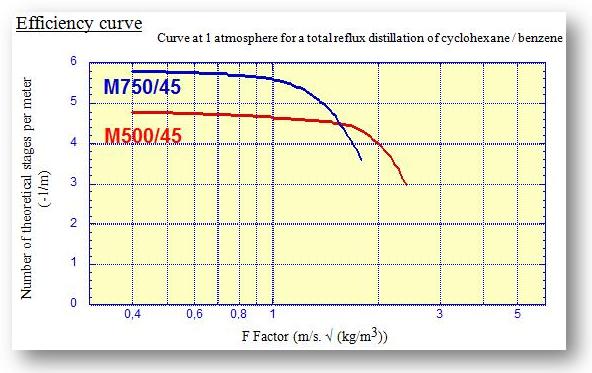

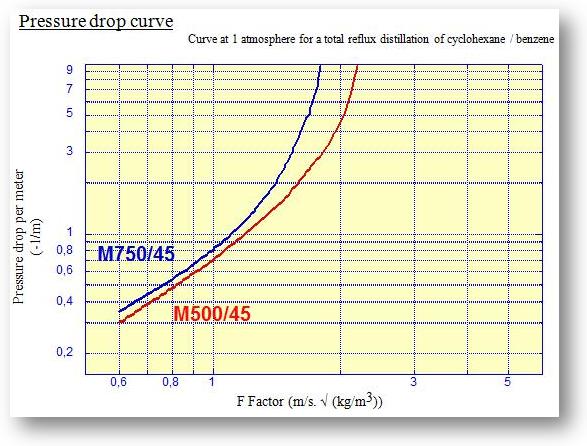

Efficiency The efficiency of a structured packing is expressed in number of theoretical plates per meter of packing and the pressure drop in Pascal per meter. These two parameters may change as a function of the following variables : • the load factor F (in m/s.kg/m 3 ) • the pressure drop • the fluid nature As a first approach we have plotted hereby these different values for the total reflux distillation of cyclohexane and benzene with different packing at the atmospheric pressure.

Packing assembling and installation The M and P type structured packing is in a block form which height is generally 270 mm or 290 mm (depending on the angle). The structured packing is laying on a support grid. To warrant a good efficiency a liquid distributor has to be installed on the top of the packing. A liquid re-distributor may be required when the packing height exceeds about 5 meters . A hold down grid may be installed to prevent the packing bed to lift in case of a wrong operation.

Column with metallic structured packing M 350/45

OPERATING CURVES M 125 Specific surface area of KEMPRO structured packing : 125 m 2 / m 3 ; angles 30° and 45°

OPERATING CURVES M 250 Specific surface area of KEMPRO structured packing : 250 m 2 / m 3 ; angles 30° and 45°

OPERATING CURVES M 350 Specific surface area of KEMPRO structured packing : 350 m 2 / m 3 ; angles 30° and 45°

OPERATING CURVES M 500 & M 750 Specific surface area of KEMPRO structured packing : 500 m 2 / m 3 & 750 m 2 / m 3 ; angle 45°

|